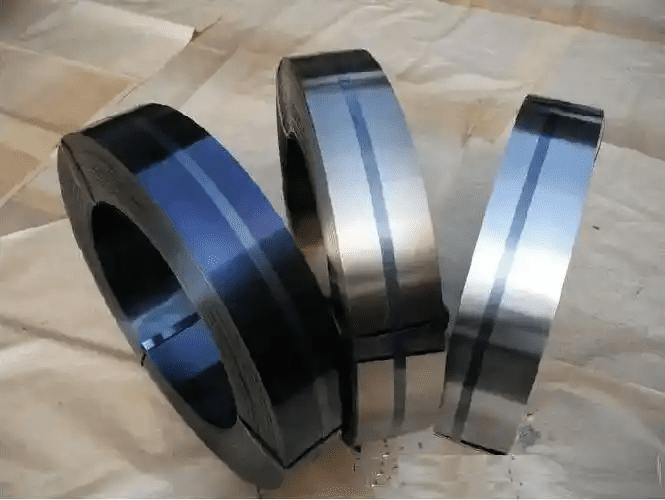

What’S The Difference Between A Black Spring And A Blue Spring?

Blackening And Bluing Are Commonly Used Steel Surface Treatments In The Industrial Manufacturing Industry. The Purpose Is To Improve The Anti-Rust And Anti-Corrosion Ability Of Steel Parts And Increase The Beauty. The Process Of Blackening And Bluing Is Exactly The Same.

The Difference Is Only That The Final Treatment Results Are Different Due To The Difference In Temperature.

In Many Cases, The Surface Blackening Of Parts Is Also Called Blue Treatment. The Principle Is Actually Very Simple, The Surface Of The Steel Material Is Oxidized, So That It Forms A Dense Oxide Film, Iron Oxide Protective Layer To Improve The Anti-Rust Ability Of The Steel.

Blackening Treatment Is Now Commonly Used Methods, There Are Traditional Alkaline Heating Blackening And The Emergence Of Late Room Temperature Blackening Two.

However, The Effect Of Normal Temperature Blackening Process Is Not Good For Low Carbon Steel. The Ferric Oxide Formed At A High Temperature Of 550 Degrees Shows A Sky Blue Color, So It Is Called Blue Treatment.

Iron Oxide Formed At A Low Temperature Of 350 Degrees Presents A Dark Color, So It Is Called Black Treatment. Bluing Treatment Is Generally Used In Weapons Manufacturing, And Blackening Treatment Is Generally Used In Mechanical Parts.

I Wish Everyone Can Find Their Own Hardware Accessories, Xiamen Hongsheng Spring Welcome Your Choice!