In the realm of metal component manufacturing, precision and efficiency are paramount. As an export manufacturer specializing in metal parts, we understand the significance of leveraging advanced tools and techniques to streamline production processes. Among the plethora of tools available, spring clamps emerge as indispensable allies, revolutionizing the way we approach various fabrication tasks.

Enhancing Precision and Stability

One of the primary advantages of spring clamps lies in their ability to provide unparalleled precision and stability during the manufacturing process. Unlike traditional clamping methods, which may require considerable manual effort and adjustment, spring clamps offer a convenient and reliable solution. By securely holding workpieces in place, these clamps minimize the risk of slippage or misalignment, ensuring consistent and accurate results.

Facilitating Quick Setups and Changeovers

In the fast-paced environment of metal component manufacturing, time is of the essence. Spring clamps excel in facilitating quick setups and changeovers, enabling seamless transitions between different production stages. Their intuitive design allows operators to swiftly position and secure workpieces, reducing downtime and maximizing overall efficiency. Whether adjusting for varying part sizes or transitioning between different machining operations, spring clamps prove invaluable in maintaining optimal workflow momentum.

Optimizing Accessibility in Complex Geometries

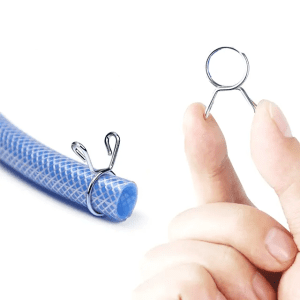

Metal components often feature intricate geometries and hard-to-reach areas, posing challenges for traditional clamping methods. Herein lies another area where spring clamps shine, thanks to their versatility and accessibility. With their compact size and flexible jaws, these clamps excel in gripping workpieces securely, even in confined spaces or irregular shapes. This capability not only expands the scope of components that can be efficiently manufactured but also minimizes the need for specialized fixtures or custom clamping solutions.

Promoting Ergonomic Work Environments

The well-being of our workforce is a top priority, and spring clamps play a role in promoting ergonomic work environments. By reducing the physical strain associated with manual clamping operations, these tools contribute to enhanced operator comfort and safety. The ergonomic benefits of spring clamps extend beyond mere convenience, fostering a culture of workplace well-being and productivity.

Driving Cost-Efficiency and Competitive Edge

In the competitive landscape of global manufacturing, cost-efficiency is paramount for sustaining profitability and gaining a competitive edge. Spring clamps contribute to this objective by streamlining production processes and minimizing resource wastage. Their ability to optimize material usage, reduce rework, and enhance overall productivity translates into tangible cost savings in the long run. By investing in advanced tools like spring clamps, manufacturers can position themselves for success in a demanding market environment.

the Versatility of Spring Clamps Across Industries

In the realm of industrial tools and equipment, few items offer the versatility and utility of spring clamps. These simple yet effective devices have found applications across various sectors, proving indispensable in numerous industries. From construction to woodworking, and from automotive to electronics, spring clamps play a pivotal role in facilitating efficient operations. Let’s delve into the diverse industries where spring clamps find their place and the unique benefits they offer in each sector.

- Woodworking Industry:

In the woodworking industry, precision and stability are paramount. Spring clamps excel in securing workpieces during cutting, drilling, sanding, and assembly processes. Their compact size and strong grip make them ideal for holding together glued joints or securing delicate pieces without causing damage. Whether in professional carpentry workshops or DIY enthusiasts’ garages, spring clamps are valued for their reliability and ease of use. - Construction Sector:

In the construction sector, where projects often involve handling heavy materials and complex structures, spring clamps offer a practical solution for temporary fastening and alignment. From securing temporary fixtures and scaffolding to holding together formwork during concrete pouring, these clamps provide a quick and efficient means of achieving stability and precision on-site. Their ability to withstand rugged conditions and repetitive use makes them indispensable tools for contractors and builders. - Automotive Manufacturing:

The automotive industry demands precision and efficiency at every stage of production. Springs find their place in automotive manufacturing facilities, where they are utilized for various tasks such as holding components in place during assembly, securing wiring harnesses, or temporarily fastening trim pieces. Their quick-release mechanism and adjustable grip make them invaluable for accommodating different part sizes and shapes, thereby streamlining production processes and ensuring consistent quality. - Electronics Assembly:

In the electronics industry, where delicate components require careful handling and precise positioning, spring clamps offer a gentle yet secure means of holding circuit boards, cables, and small parts in place during assembly and soldering. Their non-marring jaws and adjustable tension make them suitable for working with sensitive electronic components without causing damage. From small-scale prototyping labs to large-scale electronics manufacturing facilities, springs play a vital role in ensuring the quality and reliability of electronic products. - Arts and Crafts:

Beyond industrial applications, springs have also found their way into the realm of arts and crafts. Whether in sculpting, painting, or jewelry making, these clamps provide a convenient way to hold materials together while allowing artists and artisans to focus on their creative endeavors. From securing canvas frames and holding pieces in place for glue or paint to providing an extra hand during intricate assembly tasks, springs are cherished tools in the hands of creative minds.

In conclusion, the incorporation of spring clamps into metal component manufacturing processes represents a strategic investment in precision, efficiency, and competitiveness. From enhancing precision and stability to facilitating quick setups and accessibility in complex geometries, these versatile tools offer a myriad of benefits. By embracing innovation and harnessing the capabilities of spring, manufacturers can elevate their operations to new heights of excellence and profitability.