What Are The Different Types Of Wire Forming Guidelines?

Wire Forming Guides Are Resources That Provide Information And Guidance On Wire Forming Techniques, Processes, And Applications. These Guides Are Designed To Help Manufacturers, Designers, And Engineers Understand The Principles And Best Practices Of Wire Forming And Apply Them To Their Specific Needs.

While The Specific Wire Forming Guides Available May Vary Depending On The Industry And Application, Let’S Explore Some Of The Most Common Types Of Wire Forming Guides:

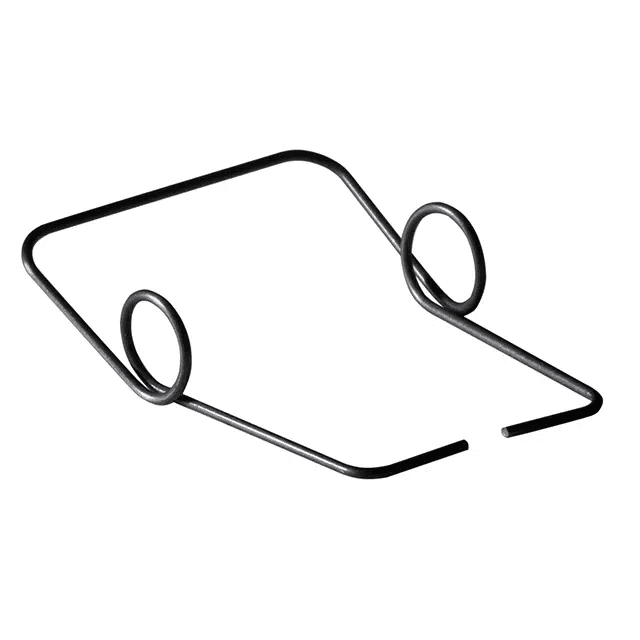

1. Wire Forming Design Guides: Wire Forming Design Guides Provide Information On The Design Principles And Considerations For Wire-Formed Products. These Guides Cover Topics Such As Wire Selection, Material Properties, Dimensions, Tolerances, And Surface Finishes.

They Also Provide Guidance On Designing Wire-Formed Products For Specific Applications, Such As Springs, Wire Mesh, And Wire-Based Assemblies. Wire Forming Design Guides Help Ensure That Wire-Formed Products Meet The Required Specifications And Performance Criteria.

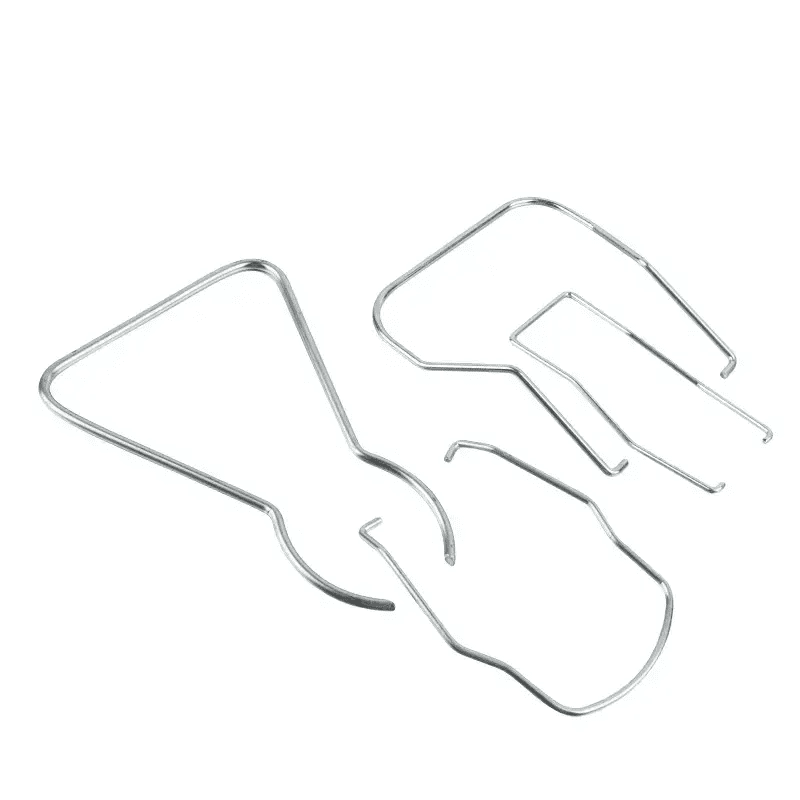

2. Wire Forming Process Guides: Wire Forming Process Guides Provide Information On The Various Techniques And Processes Used In Wire Forming, Such As Wire Bending, Cutting, Shaping, And Joining.

These Guides Cover Topics Such As Equipment Selection, Tooling Design, Process Parameters, And Quality Control Procedures. They Also Provide Guidance On Troubleshooting Common Issues And Optimizing Wire Forming Processes For Efficiency And Quality. Wire Forming Process Guides Help Ensure That Wire-Formed Products Are Manufactured Consistently And Reliably.

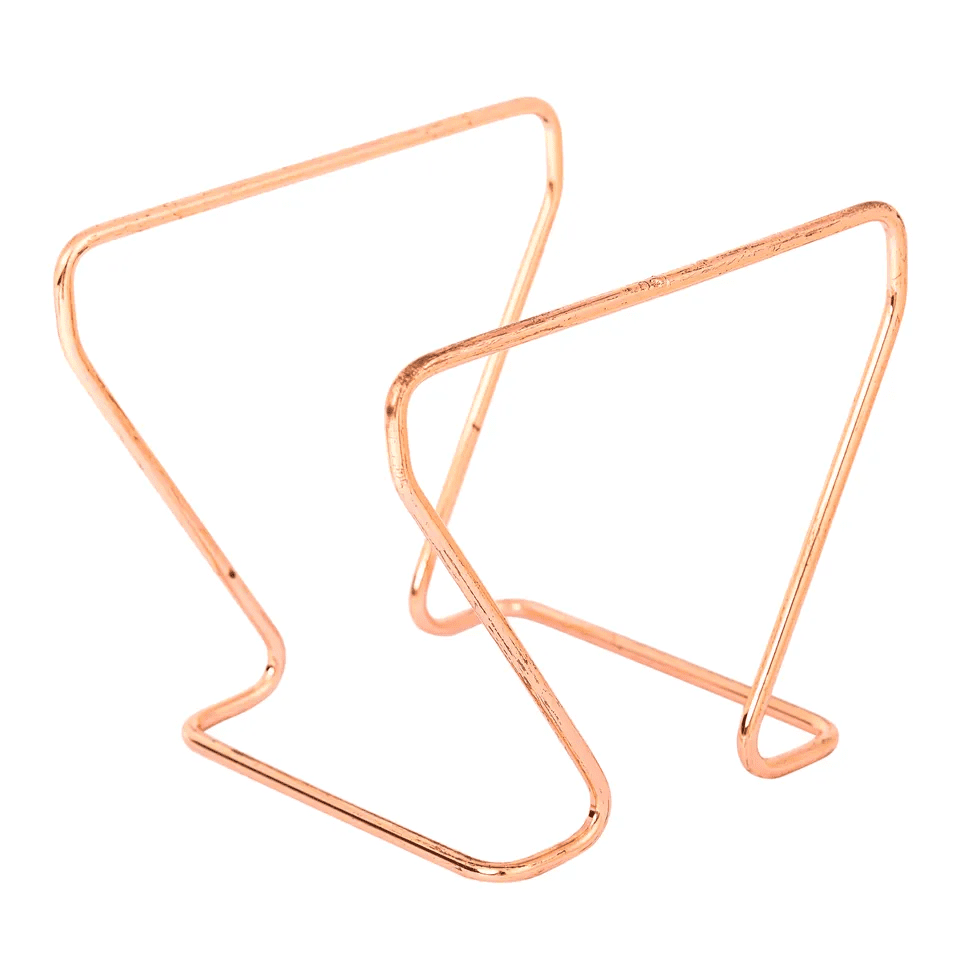

3. Wire Forming Material Guides: Wire Forming Material Guides Provide Information On The Properties And Characteristics Of Wire Materials Used In Wire Forming, Such As Steel, Copper, Aluminum, And Titanium.

These Guides Cover Topics Such As Material Selection, Mechanical Properties, Corrosion Resistance, And Heat Treatment. They Also Provide Guidance On The Advantages And Limitations Of Different Wire Materials For Specific Applications. Wire Forming Material Guides Help Ensure That Wire-Formed Products Are Made From The Appropriate Materials For Their Intended Use.

4. Wire Forming Safety Guides: Wire Forming Safety Guides Provide Information On The Safety Considerations And Best Practices For Wire Forming Processes. These Guides Cover Topics Such As Machine Guarding, Personal Protective Equipment (Ppe), Electrical Safety, And Hazard Communication.

They Also Provide Guidance On Identifying And Mitigating Potential Hazards In Wire Forming Processes. Wire Forming Safety Guides Help Ensure That Wire Forming Processes Are Conducted Safely And Prevent Workplace Accidents And Injuries.

5. Wire Forming Quality Control Guides: Wire Forming Quality Control Guides Provide Information On The Quality Control Procedures And Standards For Wire-Formed Products. These Guides Cover Topics Such As Inspection Methods, Testing Procedures, And Acceptance Criteria.

They Also Provide Guidance On Identifying And Addressing Quality Issues In Wire-Formed Products. Wire Forming Quality Control Guides Help Ensure That Wire-Formed Products Meet The Required Quality Standards And Specifications.

6. Wire Forming Application Guides: Wire Forming Application Guides Provide Information On The Various Applications Of Wire-Formed Products In Different Industries, Such As Automotive, Aerospace, Medical Devices, And Consumer Products.

These Guides Cover Topics Such As Product Design, Material Selection, Performance Criteria, And Regulatory Requirements. They Also Provide Guidance On The Advantages And Limitations Of Wire-Formed Products For Specific Applications. Wire Forming Application Guides Help Ensure That Wire-Formed Products Are Designed And Manufactured To Meet The Specific Needs And Requirements Of Their Intended Applications.

It’S Important To Note That The Specific Wire Forming Guides Available May Vary Depending On The Industry, Application, And Region. Manufacturers, Designers, And Engineers Should Consult The Relevant Industry Associations, Standards Organizations,

And Regulatory Bodies To Access The Appropriate Wire Forming Guides For Their Specific Needs. Adhering To These Guides Helps Ensure That Wire-Formed Products Are Designed, Manufactured, And Used Safely, Efficiently, And Effectively.

I Wish Everyone Can Find Their Own Hardware Accessories, Xiamen Hongsheng Spring Welcome Your Choice!