In the realm of mechanical components export manufacturing, the significance of Micro Spring cannot be overstated. These diminutive yet robust components play a pivotal role in ensuring the precision, reliability, and efficiency of various machinery across industries. In this blog post, we delve into the intricacies of Micro Springs, exploring their applications, manufacturing processes, and the indispensable role they play in the global market.

Unveiling the Versatility of Micro Springs

Micro Springs are miniature mechanical marvels that find application in a myriad of industries, ranging from automotive and aerospace to medical devices and consumer electronics. Their versatility lies in their ability to provide controlled force and movement in confined spaces, thereby optimizing the functionality of intricate systems. Whether it’s maintaining electrical contacts, regulating pressure, or absorbing shock, Micro Springs serve as indispensable components in a wide array of applications.

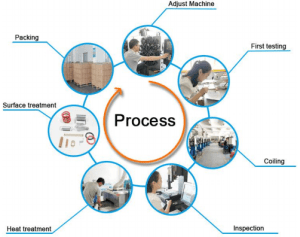

Precision Manufacturing: Crafting Micro Springs with Perfection

The manufacturing process of Micro Springs demands meticulous attention to detail and precision engineering. Utilizing advanced techniques such as CNC machining and wire EDM (Electrical Discharge Machining), manufacturers can fabricate Springs with unparalleled accuracy and consistency. The choice of materials, including stainless steel, titanium, and various alloys, is crucial in ensuring the durability and performance of these miniature springs in diverse operating environments.

Applications Across Industries: Powering Innovation and Progress

In the automotive industry, Micro Spring play a vital role in fuel injection systems, suspension components, and transmission mechanisms. Their ability to deliver precise force and motion control enhances vehicle performance and fuel efficiency. Similarly, in the medical sector, Micro Springs find application in devices such as insulin pumps, surgical instruments, and implantable devices, where reliability and miniaturization are paramount.

Meeting Global Demand: Driving Export Manufacturing Excellence

As a leading exporter of mechanical components, our commitment to excellence extends to the production of Micro Springs. Leveraging state-of-the-art manufacturing facilities and stringent quality control measures, we ensure that our Micro Springs meet the exacting standards of our global clientele. With a focus on continuous innovation and customer satisfaction, we strive to be at the forefront of the Micro Spring industry, meeting the evolving needs of diverse markets worldwide.

Cleaning and maintenance of Micro Springs

- 1. Gentle Cleaning Techniques

Micro Springs, often found in intricate mechanisms, can accumulate dust, debris, or lubricant residues over time. Regular and gentle cleaning is vital to prevent these particles from affecting the springs’ functionality. Using a soft brush, compressed air, or a mild cleaning solution can help remove contaminants without causing damage. It’s crucial to handle the springs with care during the cleaning process to avoid any deformation. - 2. Inspection for Wear and Tear

Regular inspection is a key aspect of Micro Spring maintenance. Examine the springs for signs of wear, corrosion, or fatigue. Any visual irregularities should be addressed promptly to prevent further damage. If any Micro Springs show signs of deformation or reduced elasticity, they should be replaced to maintain the overall efficiency of the mechanical system. - 3. Lubrication for Optimal Performance

Proper lubrication is essential for Micro Springs, as it ensures smooth operation and minimizes friction. However, it’s crucial to use the right type of lubricant in minimal quantities, as excess lubrication can attract dust and particles. Applying a small amount of high-quality lubricant at regular intervals will contribute to the springs’ longevity and sustained performance. - 4. Protection from Harsh Environments

Springs operating in challenging environments, such as high temperatures or corrosive atmospheres, require additional protection. Implementing protective measures, such as coatings or enclosures, can shield the springs from external factors that might compromise their integrity. This proactive approach to environmental protection is integral to the overall maintenance strategy. - 5. Professional Maintenance Services

In some cases, intricate mechanical systems may benefit from professional maintenance services. Seeking the expertise of technicians familiar with Micro Springs and their applications can ensure a thorough inspection and maintenance routine. Professional services can identify potential issues early on, preventing costly repairs or replacements down the line.

In conclusion, the proper cleaning and maintenance of Springs are paramount for ensuring their continued precision and reliability. By incorporating regular cleaning practices, conducting thorough inspections, applying appropriate lubrication, and protecting against harsh environments, manufacturers and users alike can extend the lifespan of Springs and optimize the performance of mechanical systems. A proactive approach to maintenance not only preserves the integrity of Springs but also contributes to the overall efficiency and longevity of the machinery in which they operate.

Conclusion: Empowering Efficiency and Innovation

In conclusion, Micro Springs represent more than just miniature components; they embody precision, reliability, and innovation in the realm of mechanical engineering. As exporters of these indispensable components, we recognize the pivotal role they play in powering efficiency and driving progress across industries. With a steadfast commitment to quality and customer satisfaction, we continue to push the boundaries of excellence in Spring manufacturing, contributing to the advancement of global manufacturing capabilities.

Incorporating Springs into mechanical components isn’t just about adding another part; it’s about enhancing precision, reliability, and efficiency. Their small size belies their significant impact on the performance of various systems. Through meticulous manufacturing processes and a deep understanding of their applications, we can harness the power of Micro Springs to drive innovation and progress in export manufacturing.