Springs Are Mechanical Devices That Store And Release Energy When They Are Compressed, Stretched, Or Twisted. They Are Used In A Wide Range Of Applications, From Simple Toys To Complex Industrial Machinery. There Are Many Different Types Of Springs Available, Each With Its Own Unique Characteristics And Advantages. Two Of The Most Common Types Of Springs Are Torsion Springs And Compression Springs. In This Response, We Will Explore The Differences Between These Two Types Of Springs.

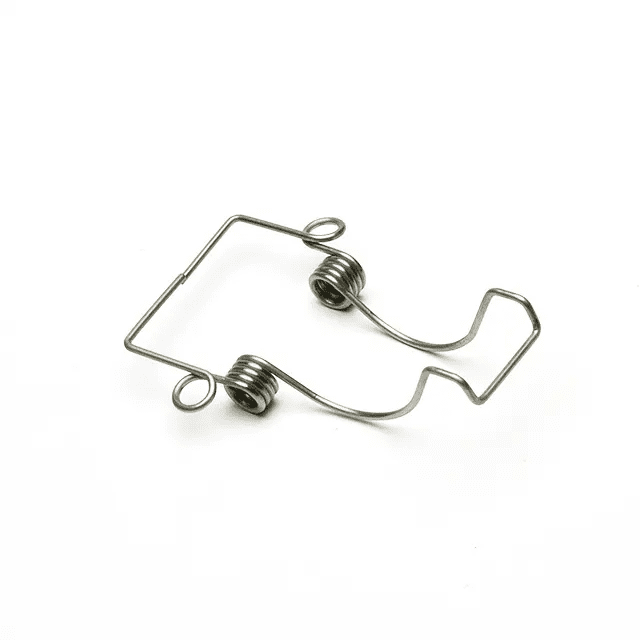

Torsion Springs, As Mentioned Earlier, Work By Twisting Or Rotating Around An Axis. They Are Typically Made From A Round Wire Or Rod, And Are Wound Tightly In A Spiral Shape. When A Force Is Applied To The Ends Of The Spring, It Twists Around Its Axis, Storing Energy In The Process. When The Force Is Released, The Spring Unwinds, Releasing The Stored Energy.

Compression Springs, On The Other Hand, Work By Compressing Or Squeezing Together. They Are Typically Made From A Round Wire Or Rod, And Are Wound Tightly In A Helical Shape. When A Force Is Applied To The Ends Of The Spring, It Compresses, Storing Energy In The Process. When The Force Is Released, The Spring Expands, Releasing The Stored Energy.

One Of The Main Differences Between Torsion Springs And Compression Springs Is The Direction In Which They Apply Force. Torsion Springs Apply Force In A Twisting Or Rotational Direction, While Compression Springs Apply Force In A Linear Direction. This Means That Torsion Springs Are Often Used In Applications Where Rotational Force Is Required, Such As In Garage Doors Or Industrial Machinery, While Compression Springs Are Often Used In Applications Where Linear Force Is Required, Such As In Shock Absorbers Or Suspension Systems.

Another Difference Between Torsion Springs And Compression Springs Is Their Range Of Motion. Torsion Springs Typically Have A Limited Range Of Motion, As They Can Only Twist Or Rotate Around Their Axis. Compression Springs, On The Other Hand, Have A Much Wider Range Of Motion, As They Can Compress And Expand In A Linear Direction. This Makes Compression Springs More Versatile And Adaptable To A Wider Range Of Applications.

Torsion Springs And Compression Springs Also Differ In Terms Of Their Design And Construction. Torsion Springs Are Typically Made From A Single Piece Of Wire Or Rod, Which Is Wound Tightly In A Spiral Shape. Compression Springs, On The Other Hand, Are Typically Made From Multiple Coils Of Wire Or Rod, Which Are Wound Tightly In A Helical Shape. This Difference In Design And Construction Can Affect The Strength, Durability, And Performance Of The Spring.

Finally, Torsion Springs And Compression Springs Differ In Terms Of Their Applications And Uses. Torsion Springs Are Often Used In Applications Where Rotational Force Is Required, Such As In Garage Doors, Industrial Machinery, And Toys. Compression Springs Are Often Used In Applications Where Linear Force Is Required, Such As In Shock Absorbers, Suspension Systems, And Valves.

In Conclusion, Torsion Springs And Compression Springs Are Two Of The Most Common Types Of Springs Used In A Wide Range Of Applications. While They Share Some Similarities, Such As Their Ability To Store And Release Energy, They Also Have Several Key Differences, Including The Direction In Which They Apply Force, Their Range Of Motion, Their Design And Construction, And Their Applications And Uses. By Understanding These Differences, It Is Possible To Choose The Right Type Of Spring For A Particular Application, Based On Its Unique Requirements And Specifications.

I Wish Everyone Can Find Their Own Hardware Accessories, Xiamen Hongsheng Spring Welcome Your Choice!