What Machines Are Used To Make Wire Forms?

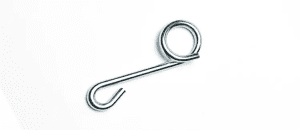

The Machine Used To Make Wire Forms Is Called A Wire Forming Machine. This Specialized Equipment Is Designed To Shape Wire Into Various Three-Dimensional Forms, Such As Hooks, Clips, Springs, Brackets, And Other Custom Shapes. Wire Forming Machines Come In Different Types And Configurations, Ranging From Manual To Fully Automated Systems, Depending On The Complexity And Volume Of Wire Forms Being Produced.

Manual Wire Forming Machines:

Manual Wire Forming Machines Are Typically Used For Low-Volume Production Or Prototyping. These Machines Require An Operator To Manually Feed The Wire Into The Machine And Manipulate It To Achieve The Desired Shape. They Are Often Equipped With Various Tools, Dies, And Fixtures That Aid In Bending, Cutting, And Shaping The Wire. The Operator’S Skill And Experience Play A Crucial Role In Achieving Accurate And Consistent Results.

Semi-Automated Wire Forming Machines:

Semi-Automated Wire Forming Machines Combine Manual Operations With Some Automated Features. These Machines Are Designed To Streamline The Wire Forming Process And Increase Productivity. They May Include Features Such As Motorized Wire Feeding, Automatic Bending Mechanisms, And Programmable Controls. The Operator Still Plays A Significant Role In Setting Up The Machine, But The Automation Helps Reduce Manual Effort And Improve Efficiency.

Cnc Wire Forming Machines:

Cnc (Computer Numerical Control) Wire Forming Machines Are Highly Automated And Offer Precise Control Over The Wire Forming Process. These Machines Are Equipped With Computer-Controlled Systems That Allow For Complex And Intricate Wire Forms To Be Produced With High Accuracy And Repeatability. Cnc Machines Use Software Programs To Control The Movement Of The Wire, Ensuring Precise Bending, Cutting, And Shaping Operations. They Often Feature Multiple Axes Of Movement, Allowing For The Creation Of Intricate Wire Forms.

Multi-Station Wire Forming Machines:

Multi-Station Wire Forming Machines Are Designed To Perform Multiple Operations In A Single Setup. These Machines Consist Of Several Workstations, Each Dedicated To A Specific Operation, Such As Bending, Cutting, Or Shaping. The Wire Is Fed Through The Machine, And As It Progresses From One Station To The Next, Different Operations Are Performed Simultaneously Or Sequentially. This Setup Allows For Increased Productivity And Reduced Cycle Times.

Rotary Wire Forming Machines:

Rotary Wire Forming Machines Are Specialized Machines Used For Producing Wire Forms With Circular Or Helical Shapes, Such As Springs Or Coils. These Machines Utilize A Rotating Mandrel Or Spindle Around Which The Wire Is Wrapped Or Coiled. The Wire Is Fed Into The Machine, And As The Mandrel Rotates, It Guides The Wire To Form The Desired Shape. Rotary Wire Forming Machines Can Be Manual Or Automated, Depending On The Complexity And Volume Of Production.

Each Type Of Wire Forming Machine Has Its Advantages And Is Chosen Based On The Specific Requirements Of The Wire Forms Being Produced. Factors Such As Production Volume, Complexity Of Shapes, Accuracy, And Automation Level Influence The Selection Of The Appropriate Machine. Regardless Of The Type, Wire Forming Machines Play A Crucial Role In Transforming Raw Wire Into Functional And Precise Three-Dimensional Forms Used In Various Industries.

I Wish Everyone Can Find Their Own Hardware Accessories, Xiamen Hongsheng Spring Welcome Your Choice!